Scrap Battery Recycling Production Line

With the rapid development of new energy technology, lithium battery recycling industry has also ushered in explosive growth, for the recycling of waste lithium batteries is also a problem to be solved at present, waste lithium batteries are commonly recycled three kinds of processing technology: physical dismantling and separation, hydrometallurgical extraction, and fire treatment process. Physical dismantling and separation method is often used: lithium battery recycling equipment dry crushing and sorting system, and the recovery rate of rare metals.

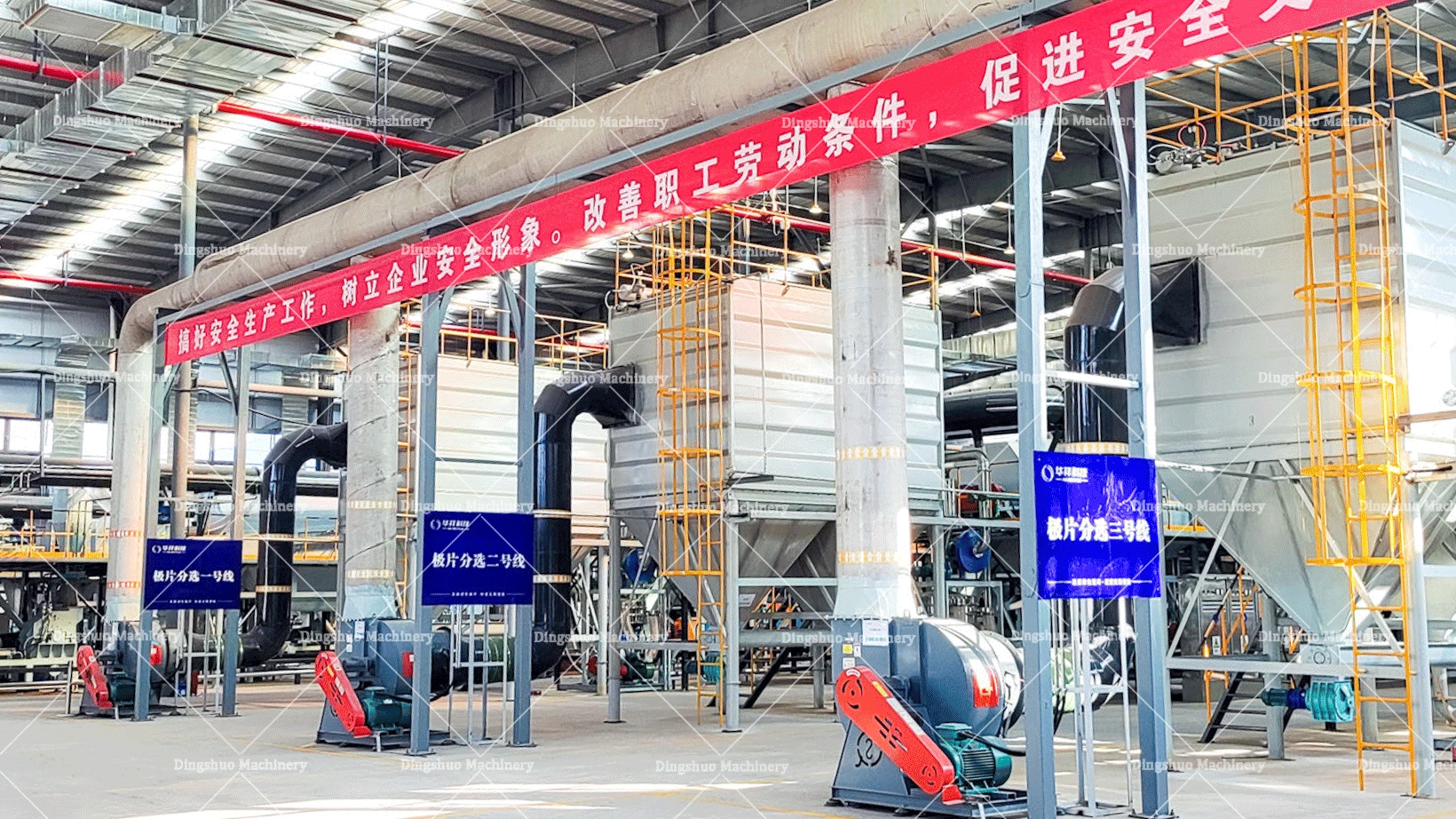

1. Physical crushing and sorting process: the waste lithium batteries through the conveyor belt to the shredder for shredding and dismantling, and then through the crusher for secondary crushing, through the airflow sorting machine will be the plastic diaphragm extraction separation collection. The material is then crushed by the crusher, and the crushed material is screened by linear vibrating screen for many times. Sieve out part of the black powder, the rest of the material after the second grinding for the second screening, the remaining black powder for collection and processing. The copper and aluminium mixture is then put into the specific gravity sorter to sieve out the copper and aluminium chips. The whole process is equipped with a negative pressure collection system to collect the dust generated. The waste gas generated in the process is purified and treated, and then discharged at high altitude after reaching the standard.

2. Wet metallurgy extraction: The separated black powder is soaked with acid or alkali, and the metal elements in the solution are separated and purified through precipitation, extraction and other chemical methods. Thus, the elemental separation of metals is realised.

3. Pyrometallurgy: the battery material through the high temperature way, there are organic matter for oxidation and cracking, from metal to oxide, so it becomes pyrometallurgy.

Compared to the above three ways, hydrometallurgical process is relatively more complex, but more advantageous for resource treatment, this process requires many chemical additives, the chemical cost requirements are higher. Pyrometallurgy is relatively simple, but it consumes a lot of energy, and it is easy to cause pollution, the important thing is that the valuable metals can not be completely recycled. Lithium battery recycling equipment using dry physical separation method, lower energy consumption, separation and recovery of high purity, and small energy consumption, will not cause pollution to the environment, environmental protection and convenient.