Lithium Battery Recycling Trend

The following are some advanced lithium battery recycling powdering technologies:

The following are some advanced lithium battery recycling powdering technologies:

I. Mechanical Crushing and Screening Technology:

1.Principle: By using equipment such as crushers and pulverizers, used lithium batteries are crushed to turn them into smaller particles. Then, through screening equipment, black powder and other substances are separated based on the difference in particle size. For instance, a crusher is first used for initial crushing, then a mill is employed for fine grinding, and finally a vibrating screen is utilized for screening.

2. Advantages: The operation process is relatively simple, the equipment cost is low, it can handle a large number of used lithium batteries, and it has certain universality for different types of lithium batteries.

3. Disadvantages: During the crushing process, heat is easily generated. If heat dissipation is not timely, it may cause safety issues, such as battery thermal runaway. And it may damage the structure of some materials in lithium batteries, affecting the subsequent recycling efficiency.

Ii. Pyrolysis Technology

Principle: Place used lithium batteries in a high-temperature, oxygen-free or oxygen-deficient environment to cause thermal decomposition reactions of the organic components within the batteries. After pyrolysis, the organic matter in the battery will be transformed into gas, liquid and solid residues, and the black powder among them can be recovered through subsequent processing.

2. Advantages: It can effectively remove impurities such as organic binders from used lithium batteries and improve the purity of black powder. Meanwhile, the gases and liquids produced during the pyrolysis process can be further processed and utilized to achieve comprehensive resource recovery.

3. Disadvantages: The investment cost of pyrolysis equipment is relatively high, and it requires a large amount of energy to maintain a high-temperature environment. If the gases produced during pyrolysis are not properly treated, they may cause pollution to the environment.

Iii. Hydrometallurgical Technology

Principle: By using acids, bases or other chemical reagents, the metal components in used lithium batteries are dissolved into a solution. Then, through a series of chemical reactions and separation and purification steps, different metal elements are separated one by one, thereby obtaining black powder and other valuable metal compounds.

2. Advantages: It can achieve high-purity recovery of multiple metal elements in lithium batteries, with a relatively high recovery efficiency. For some metals that are difficult to separate by physical methods, hydrometallurgy technology has unique advantages.

3. Disadvantages: The use of chemical reagents may cause certain pollution to the environment and strict wastewater treatment is required. The process flow is rather complex, the operation is rather difficult, and it requires professional chemical knowledge and skills.

Iv. Pyrometallurgical Technology:

Principle: Used lithium batteries are smelted in a high-temperature furnace to separate the metal components from other impurities, forming metal alloys or oxides. Then, through further refining and purification processes, black powder and high-purity metal materials are obtained.

2. Advantages: It has a large processing capacity and can quickly handle a large number of used lithium batteries. For some used lithium batteries with complex components, pyrometallurgical technology can effectively achieve metal recycling.

3. Disadvantages: The high-temperature smelting process consumes a large amount of energy and has a relatively high cost. Meanwhile, during the smelting process, pollutants such as waste gas and waste residue may be produced, and corresponding environmental protection treatment facilities need to be equipped.

V. Bio-metallurgical Technology

Principle: By taking advantage of the oxidation, reduction and adsorption properties of certain microorganisms (such as bacteria, fungi, etc.), the metal components in used lithium batteries are converted into soluble compounds, and then the metals are recovered through separation and purification methods. For instance, some acidophilic bacteria can oxidize the metal sulfides in lithium batteries to sulfates, thereby dissolving the metals into the solution.

2. Advantages: It has the advantages of being environmentally friendly, low energy consumption, and mild reaction conditions. Moreover, microorganisms can be applied on a large scale through cultivation and reproduction at a relatively low cost.

3. Disadvantages: The reaction rate of the bio-metallurgical process is relatively slow, and the recovery period is long. The growth and metabolism of microorganisms are influenced by various factors, such as temperature, pH value, and nutrients, which require strict control and optimization of reaction conditions.

The market size of the lithium battery recycling and powdering industry is showing a growth trend. The following is the relevant analysis:

I. Past Market Size:

1.In 2022, according to relevant data, the volume of used lithium battery powder processed in China was 325,000 tons, representing a year-on-year increase of 62.5%. Among them, the processing volume of ternary black powder was 215,000 tons, increasing by 16.8% year-on-year. The processing volume of lithium iron phosphate black powder was 110,000 tons, representing a year-on-year increase of 175.0%.

2. From 2018 to 2023: During this period, the Ministry of Industry and Information Technology successively announced the list of 156 enterprises in five batches that met the "Industry Normative Conditions for Comprehensive Utilization of Waste Power Batteries from New Energy Vehicles". By the end of 2023, a physical recycling capacity of 1 million tons of power batteries had been built, with over 100,000 tons of lithium recoverable, ranking first in the world. In 2023, the output of lithium recycled and utilized from lithium battery materials in China was 60,000 tons, accounting for 75% of the global total and 9% of the domestic lithium salt raw materials.

3. Current market size: In 2024, China is about to enter a period of growth in the retirement of lithium batteries. According to the "2023 China Lithium Battery Industry Development Index (Suining Index)", it is expected that by 2030, the market size of lithium battery recycling will exceed 100 billion yuan, with an average annual growth rate of 26%. The volume of used lithium battery recycling will exceed 1 million tons, which is about five times that of 2022.

Ii. Future Development Trends

From the perspective of market demand, with the formation of the world's largest power battery market in China, the number of retired batteries has increased sharply. By 2028, the number of retired batteries may reach 3 million tons, and by 2038, it will even reach 30 million tons. This will provide sufficient raw materials for the lithium battery recycling and powdering industry and further expand the market size.

From a policy perspective, the state has successively introduced a series of policies to regulate the industry order. For instance, the relevant documents issued by the Ministry of Industry and Information Technology are conducive to the standardized development of the industry, improving the efficiency and quality of recycling, and promoting the growth of the market scale.

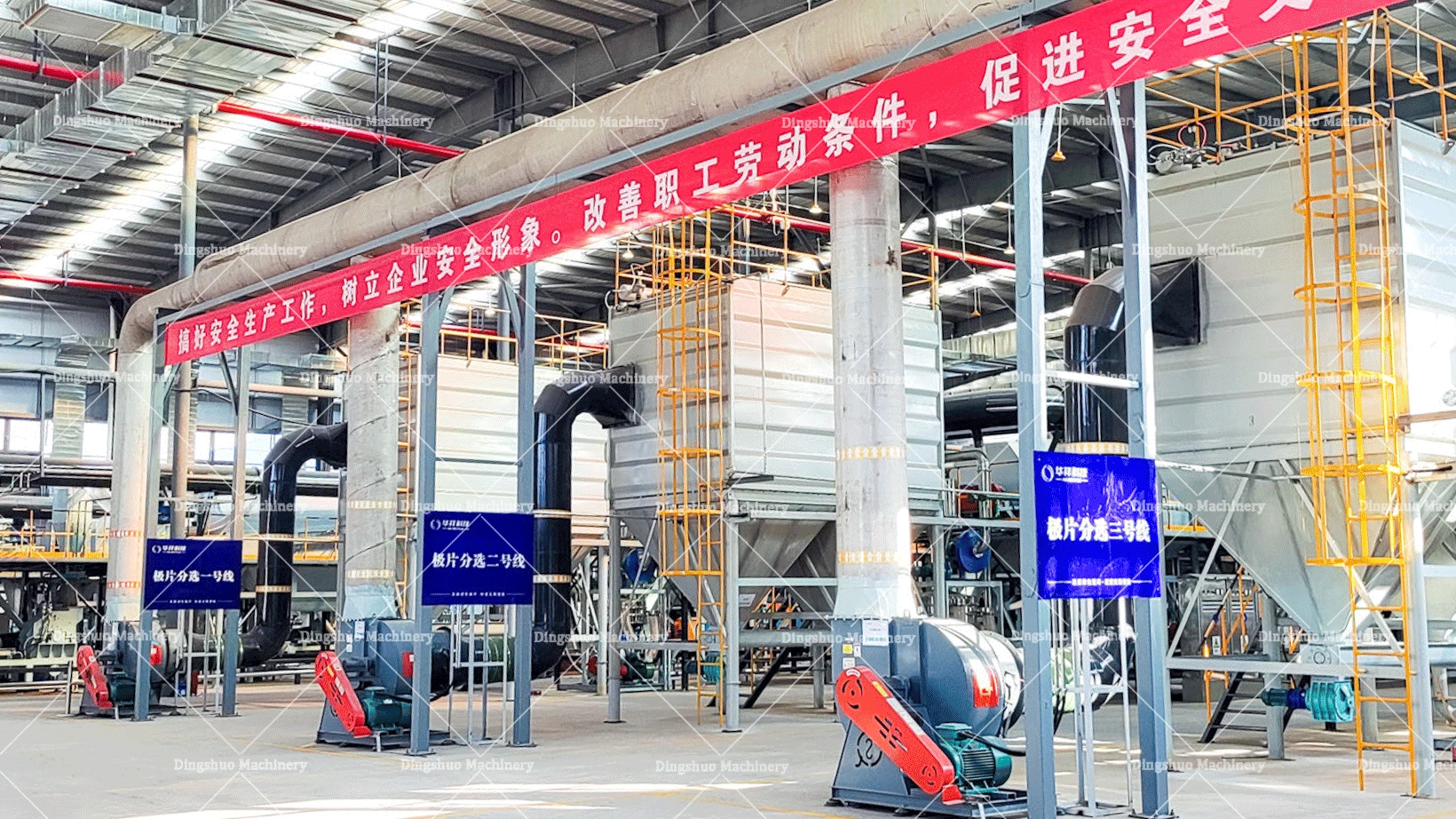

From the perspective of technological progress, the continuous development of more advanced complete sets of equipment and process lines for lithium battery crushing and recycling, as well as multi-scenario and multi-purpose comprehensive utilization methods for retired power batteries, will enhance the efficiency and benefits of recycling and utilization, attract more enterprises to enter this industry, and promote the sustained growth of the market size.

However, although the market size potential of the lithium battery recycling and powdering industry is considerable, the industry's development also faces some challenges, such as the standardization of recycling channels, the improvement of technical levels, and the satisfaction of environmental protection requirements.