Introduction To Lithium Battery Shredding Technology

Lithium battery shredding while powered on (i.e., mechanical crushing without complete discharge) is a highly complex and dangerous technical operation. The technical difficulties mainly stem from the active materials inside the lithium battery and the potential risk of energy release. The following are the core difficulties and the corresponding scientific principle analysis:

Lithium battery shredding while powered on (i.e., mechanical crushing without complete discharge) is a highly complex and dangerous technical operation. The technical difficulties mainly stem from the active materials inside the lithium battery and the potential risk of energy release. The following are the core difficulties and the corresponding scientific principle analysis:

I. Core Technical Difficulties

Short circuit and thermal runaway

The difficulty lies in that when shredding with electricity, metal fragments (such as copper foil and aluminum foil) come into contact with the positive and negative electrode materials, directly forming a short-circuit loop. The instantaneous current can reach several thousand amperes, causing a sharp increase in local temperature (thermal runaway).

Scientific mechanism

The electrolyte (LiPF₆) of lithium-ion batteries decomposes at high temperatures (>80°C), releasing PF₅ gas and generating hydrofluoric acid (HF), which further corrodes the equipment.

When the negative electrode graphite or lithium metal is exposed, it reacts with oxygen to release a large amount of heat (reaction formula: 4Li + O₂ → 2Li₂O + heat).

2. Explosive gases and dust

The difficulty lies in the fact that the lithium metal powder and electrolyte vapor (such as DMC, EC and other organic solvents) produced during the crushing process mix with air, reaching the explosion limit (the lower explosive limit of lithium dust is 20-50g/m³).

Data support

The complete combustion of 1kg of lithium battery can release approximately 3.5MJ of energy (equivalent to 0.8kg of TNT).

The explosive concentration range of electrolyte vapor in the air is 1.3%-9.5% (by volume).

3. Electrolyte leakage and toxicity

The difficulty lies in the fact that shredding leads to the leakage of the electrolyte (containing fluoride and carbonates), and its toxicity (LD50: LiPF₆ approximately 200mg/kg) and corrosiveness (pH<2) pose a threat to equipment and personnel.

Reaction chain

LiPF₆ + H₂O → HF + POxFy gas → corrodes metal equipment and burns human tissues.

4. Difficulty in material separation

The difficulty lies in that under the charged state, the positive and negative electrode materials (LiCoO₂/ graphite) and the separator (PP/PE) are difficult to separate efficiently due to electrostatic adsorption, which affects the subsequent recovery rate.

Technical bottleneck

The surface charge density of charged particles can reach 10⁻⁴-10⁻³ C/m², causing the efficiency of sorting equipment (such as electrostatic separators) to drop by 30%-50%.

Ii. Industrialization Solutions and Research Directions

1. Inert environment control

Technical solution: Shredding is carried out in a nitrogen (O₂<1%) or argon environment to suppress the combustion reaction (maintaining a pressure of 0.1-0.3MPa).

Cost challenge: Gas consumption accounts for 15% to 20% of the treatment cost.

2. Low-temperature crushing technology

Liquid nitrogen freezing: Cooling the battery to -196°C reduces the material activity (the reaction rate of lithium metal drops by 90%), but it consumes a relatively high amount of energy (about 500L of liquid nitrogen is needed for each ton of battery).

3. Real-time monitoring and fire extinguishing

Sensor network: Deploy infrared thermal imaging (for detecting sudden temperature changes), gas concentration sensors (for monitoring H₂ and CO thresholds), and pressure sensors, with a response time of less than 50ms.

Fire extinguishing system: heptafluoropropane (HFC-227ea) or fine water mist (particle size <100μm) can quickly suppress the fire.

4. Live pretreatment technology

Pulse discharge: Forced discharge within 0.1 seconds through high-frequency pulse current (>100A), but the problem of electrode melting (local temperature >300°C caused by Joule heat) needs to be solved.

Microwave discharge: Utilizing 2.45GHz microwaves to excite internal short circuits and achieve controllable energy release (laboratory stage).

Iii. Frontier Breakthrough Directions

1. Artificial intelligence prediction model: Predict the critical point of thermal runaway through electrochemical-thermal coupling simulation (such as COMSOL Multiphysics).

2. Solid electrolyte battery treatment: The new generation of solid electrolyte batteries (such as LiPON) have no risk of liquid electrolyte leakage when torn apart.

3. Supercritical fluid separation: Utilize supercritical CO₂ (temperature >31°C, pressure >7.4MPa) to dissolve the electrolyte and separate the materials.

Conclusion

The technical difficulty of shredding lithium batteries while they are charged essentially lies in the uncontrollability of energy release and the coupling effect of multiphase hazardous substances. At present, only a few enterprises (such as Umicore in Belgium and GEM in China) have mastered industrialized technology, and the processing cost is as high as $1,000 - $1,500 per ton of batteries. In the future, breakthroughs in rapid discharge, low-temperature crushing and closed-loop gas recovery technologies are needed to achieve safe and economical large-scale application.

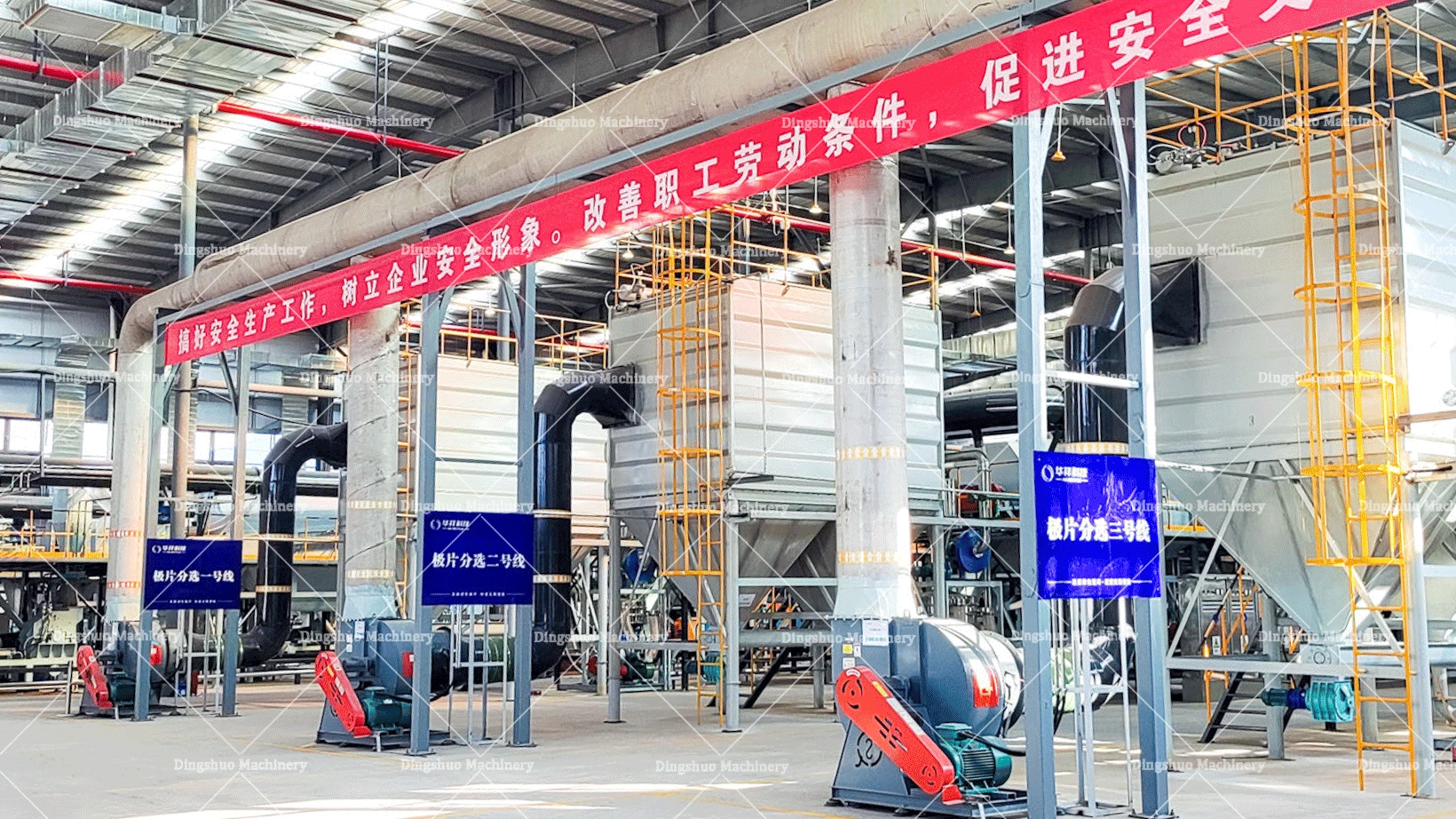

Zhengzhou Dingshuo Machinery Manufacturing Co., Ltd. has 14 years of experience in the development and manufacture of renewable energy recycling and Our new lithium battery recycling equipment developed independently, since 2011, has been in the absolute leading position in the Our machine has been exported to Vietnam, Turkey, Thailand, Italy, Switzerland, Malaysia, Japan, Myanmar, Korea, Australia. Our machines have been exported to Vietnam, Turkey, Thailand, Italy, Switzerland, Malaysia, Japan, Myanmar, Korea, Australia, Pakistan, Kazakhstan, Brazil, Russia, Singapore, Spain, Romania, Iraq, Italy, Indonesia, Thailand, France, Germany, Poland, Hungary, USA, Colombia The company has a wide range of products and services, including the following.

If interested, please Contact :Jessie Contact Email: sgmachine12@163.com Whatsapp: +86-15516907866 (Jessie is on line in 24 hours)