Summary of Lithium Battery Recycling Issues

Lithium battery recycling and processing equipment is a hot topic in the new energy industry. Many people have a lot of questions about its working principle, recycling effect, investment value, etc. The editor of Dingshuo Machinery has tallied up the issues that everyone is most concerned about and sorted out the following key points for you, hoping to help you clear up the doubts in your heart.

Lithium battery recycling and processing equipment is a hot topic in the new energy industry. Many people have a lot of questions about its working principle, recycling effect, investment value, etc. The editor of Dingshuo Machinery has tallied up the issues that everyone is most concerned about and sorted out the following key points for you, hoping to help you clear up the doubts in your heart.

Lithium battery recycling and processing equipment: Core issue answers

1. Recycling process and core technologies

Modern lithium battery recycling mainly adopts a combination of mechanical crushing and sorting with anaerobic pyrolysis technology, especially processes such as "charged crushing, continuous airless pyrolysis, and vortex crushing and classification", aiming to efficiently and environmentally recover valuable metals.

2. Difficulties in equipment processing:

During the recycling process, challenges such as waste gas treatment (such as the evaporation of electrolyte and the harmful gases produced by the thermal desorption of binder), dust control, and ensuring the purity of electrode powder need to be overcome.

3. Investment and Profit Considerations:

The industry is under pressure from declining profits, but the requirements for material recovery rates (such as extreme powder and copper and aluminum purity) are getting higher and higher. Therefore, technological innovation (such as physical repair processes and efficient pyrolysis) is crucial for improving economic efficiency.

4. Environmental Protection and Safety

Meeting exhaust gas emission standards, oxygen-free pyrolysis to prevent explosions, and integrated environmental protection designs (such as equipment that integrates functions like solvent evaporation, diaphragm pyrolysis, and waste gas incineration) are the keys to ensuring production safety and environmental protection.

5. Requirements for automation and standardization

The battery disassembly process is difficult to be fully automated due to the various battery models (currently mostly relying on manual labor). Promoting the standardization of battery design is an important direction for achieving automated disassembly and improving recycling efficiency in the future.

6. What are the main products of lithium battery recycling?

The main objective of recycling and processing is to extract valuable metals from batteries, such as lithium (Li), cobalt (Co), nickel (Ni), etc. These are usually recycled in the form of black powder (extreme powder) and then used for the production of new materials. Copper foil and aluminum foil will also be recycled at the same time.

What is the difference between "secondary utilization" and "regeneration utilization" after the recycling of used lithium batteries?

Answer: (1) Secondary utilization: It refers to the testing, classification, and reorganization of retired but not yet completely scrapped power batteries, and their application in scenarios with lower performance requirements, such as energy storage base stations and low-speed electric vehicles, to fully utilize their residual value.

(2) Recycling: It refers to the process of disassembling, crushing and refining batteries that cannot be reused through physical and chemical methods to recover valuable metals and materials, and re-enter the material manufacturing cycle.

8. Can individuals or small-scale business operators invest in lithium battery recycling and processing equipment?

Answer: The recycling and processing of lithium batteries, especially the equipment using processes such as anaerobic pyrolysis, usually have relatively high technical barriers and capital investment. The industry is currently also more inclined towards large-scale and standardized development. Individuals or small-scale investors entering this field need to carefully consider factors such as technology, environmental protection approval, and a continuous and stable source of raw materials.

9. What is the current material recovery rate of lithium battery recycling technology?

Answer: The industry has increasingly strict requirements for key indicators such as the purity and recovery rate of extreme powder and copper and aluminum. Some advanced physical recycling (powdering) equipment for electrode sheets can achieve efficient recovery and reuse of electrode powder, copper powder and aluminum powder. However, the specific recovery rate values vary depending on the equipment, process and raw materials. Generally, enterprises regard it as a core technical parameter.

10. Summary and Suggestions

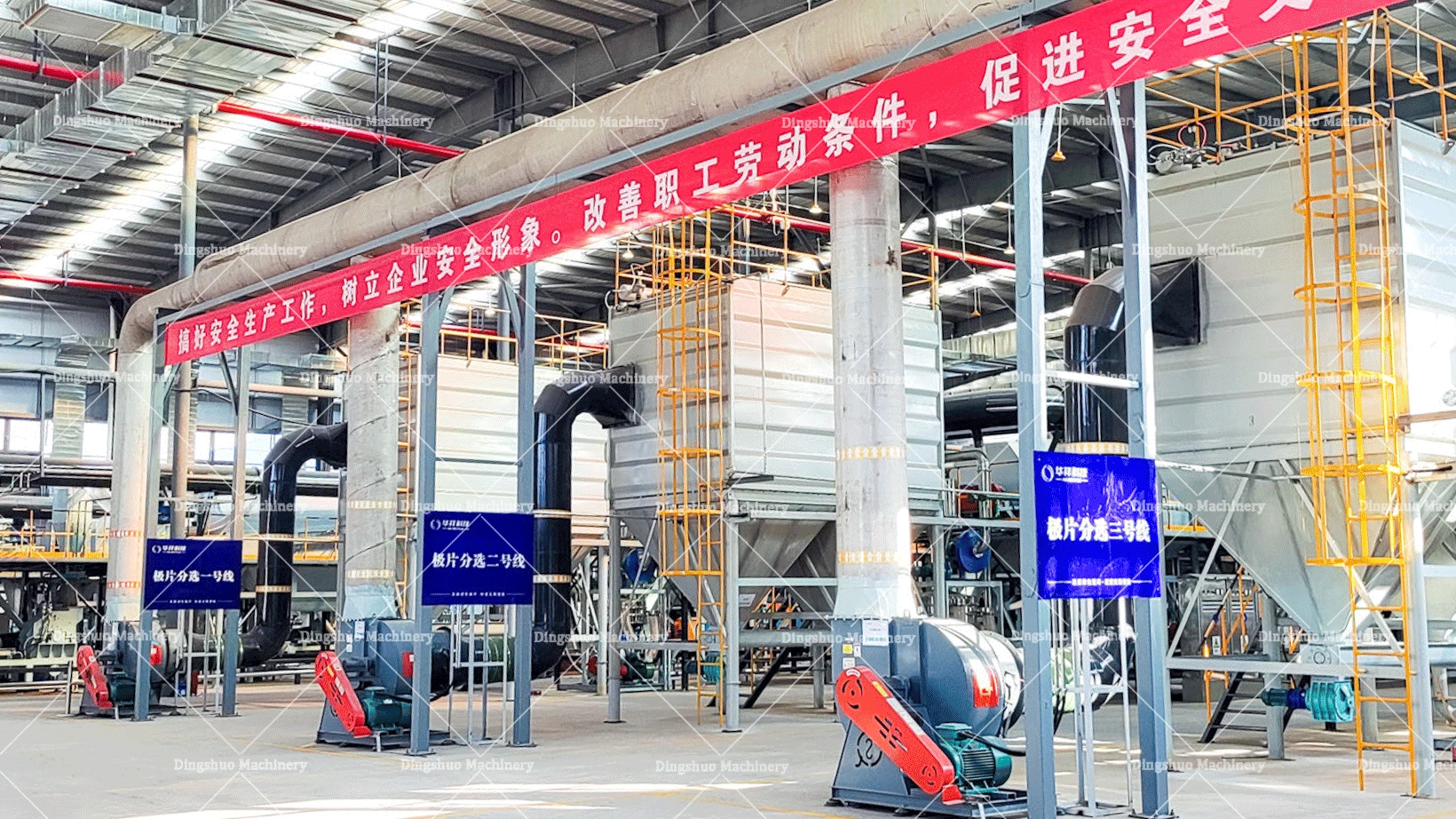

Lithium battery recycling and processing equipment is currently in a stage of rapid technological iteration and upgrading. Traditional processing methods are gradually being phased out due to environmental protection and efficiency issues. Equipment that integrates innovative technologies such as mechanical crushing, fine sorting, and anaerobic pyrolysis is becoming mainstream. They can extract valuable materials more efficiently and environmentally friendly, and improve the purity of recycled products.

However, the industry still faces challenges such as the difficulty in automated disassembly (due to the variety of battery models), high environmental and safety requirements, and the impact of fluctuations in raw material prices on profit margins. In the future, promoting the standardization of battery design, continuously enhancing the innovation and environmental friendliness of recycling technology, and establishing standardized market standards will be the keys to development.

Zhengzhou Dingshuo Machinery Manufacturing Co., Ltd. has 14 years of experience in the development and manufacture of renewable energy recycling and Our new lithium battery recycling equipment developed independently, since 2011, has been in the absolute leading position in the Our machine has been exported to Vietnam, Turkey, Thailand, Italy, Switzerland, Malaysia, Japan, Myanmar, Korea, Australia. Our machines have been exported to Vietnam, Turkey, Thailand, Italy, Switzerland, Malaysia, Japan, Myanmar, Korea, Australia, Pakistan, Kazakhstan, Brazil, Russia, Singapore, Spain, Romania, Iraq, Italy, Indonesia, Thailand, France, Germany, Poland, Hungary, USA, Colombia The company has a wide range of products and services, including the following.

If interested, please Contact :Jessie Contact Email: sgmachine12@163.com Whatsapp: +86-15516907866 (Jessie is on line in 24 hours)